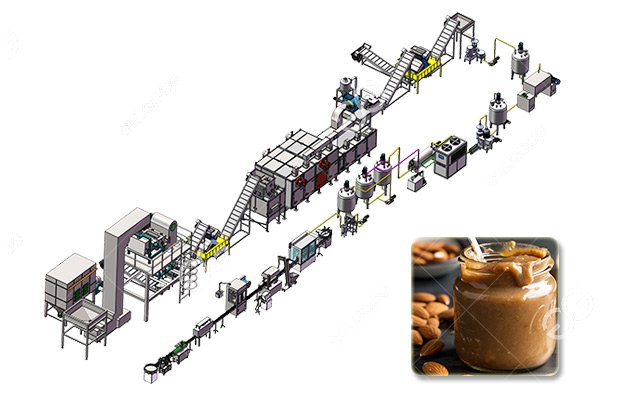

The almond butter production line can produce different flavors almond butter. Such as natural almond butter, smooth almond butter, salty almond butter, sweet almond butter, particle almond butter, etc. This line consists of shelling machine, peeling machine, roaster machine, and grinder machine.

This production line is highly automated, enabling efficient and continuous almond butter production. The equipment has an average hourly production capacity of 100-2,000 kg, meeting the needs of diverse users.

Core Equipment of Almond Butter Production Line

No.1 Almond Shelling Machine: This sheller is a simple yet effective unit designed for apricot kernel shelling. It operates through a single-stage shelling process with an adjustable clearance. Almonds are fed into the machine; any unshelled kernels can be re-shelled by fine-tuning the clearance. Our factory also offers a three-stage sheller, which grades and shells apricot kernels in one pass according to size.

No.2 Almond Peeling Machine: This machine is a high-efficiency peeling solution ideal for almonds, peanuts, soybeans, and more. It is suitable for integration into fried peanut production lines in large-scale operations. It can also peel larger nuts such as broad beans. With modified components, it is equally effective for peeling smaller almonds.

No.3 Almond Roasting Machine: This is a professional roasting unit for sesame, mung beans, soybeans, wheat, and other small grains. It features an intelligent digital temperature control system that ensures consistent and even heating. It can be used as a standalone machine or incorporated into various production lines.

No.4 Almond Butter Grinder Machine: Suitable for the food, pharmaceutical, and chemical industries, this grinder performs superfine grinding of semi-liquid and emulsion materials. It achieves crushing, emulsification, homogenization, and mixing in one process, with key performance metrics meeting advanced international standards.

No.5 Almond Butter Filling Machine: This automatic filler is designed for viscous products like almond butter, offering precise volumetric filling for jars, bottles, or pouches. Constructed from food-grade stainless steel, it ensures hygiene and easy cleaning. It can be integrated with capping and labeling machines for continuous packaging lines.

Features of Automatic Almond Butter Production Line

-

Flexible Adaptability: It can produce almond paste in a variety of flavors and sizes, including fine, granular, sweet, and savory.

-

Continuous High Production: Each piece of equipment in the production line seamlessly connects to achieve automated, continuous production and high throughput.

-

Precise Quality Control: The roasting temperature of the roaster and the grinding fineness of the paste grinder can be precisely controlled to ensure consistent almond paste flavor and quality.

-

Food Compliance: The entire production line is constructed of food-grade 304 material, making it easy to clean. The materials used meet hygiene and safety standards.

-

High Scalability: It can be used not only for almond paste, but also for producing peanut butter, cashew butter, hazelnut butter, and more. This allows for multiple uses of one machine, significantly improving equipment utilization.