The RUTF peanut paste processing line is an integrated solution specifically designed for RUTF projects. Its requirements for production equipment are far higher than those of ordinary food processing lines.

The production line not only guarantee the stable quality of the peanut paste, but also ensure reliable performance in hygiene, safety, continuous operation, and project compliance. This line is suitable for RUTF projects, nutritional food factories, and international aid programs.

Features of RUTF Peanut Paste Processing Line

- The entire line features a hygienic design, with key contact parts made of food-grade stainless steel.

- The low-moisture process is adapted to meet RUTF requirements for product stability.

- The RUTF peanut paste line operates continuously, ensuring consistent peanut paste quality.

- Automated control reduces human intervention and the risk of cross-contamination.

- The production line uses a modular structure, facilitating future expansion and maintenance.

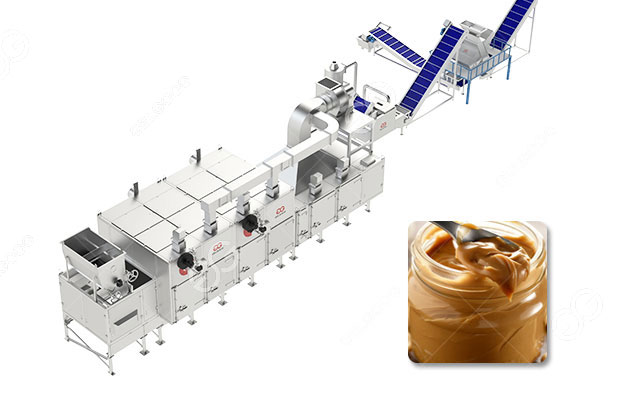

Main Equipment Components of RUTF Peanut Paste Process

- Peanut Pre-treatment Equipment: Includes cleaning and screening devices to remove impurities and abnormal raw materials.

- Peanut Roasting Equipment: Achieves uniform roasting through stable temperature control, improving flavor and reducing microbial risk. Meets the basic food safety requirements of the RUTF peanut paste project.

- Peeling System: After roasting, the peanuts are cooled and the skins are removed, ensuring clean raw materials for the grinding process.

- Peanut Grinding and Refining Equipment: Uses industrial-grade grinders or colloid mills to produce fine, uniform peanut paste, preventing separation and oil leakage.

- Mixing and Storage System: Provides a stable mixing base for subsequent addition of oils, nutrients, or premixes according to RUTF peanut paste formula requirements.

- Conveying and Connecting System: Equipment is connected through enclosed or semi-enclosed systems, reducing exposure and improving overall hygiene.

Advantages of the Turnkey RUTF Peanut Paste Processing Line

- A true turnkey solution: From peanut paste line process design and equipment configuration to installation and commissioning, everything is delivered as a complete package.

- Clear risk control: Key aspects are designed with food safety and stability in mind.

- User-friendly operation: Suitable for developing countries or project environments with varying levels of technical expertise.

- Controllable maintenance costs: The processing line has a rational structure, and wear parts are highly standardized and readily available.

GELGOOG Company not only provides RUTF peanut paste production line equipment, but also a complete solution tailored to the needs of RUTF (Ready-to-Use Therapeutic Food) projects.

Through hygienic design, stable processes, and extensive delivery experience, we help customers effectively reduce food safety risks and achieve continuous and reliable production of RUTF peanut paste.